Technology – What is a multi-plate clutch?

Everyone is currently talking about Industry 4.0. Everything is digital and controlled by computer. IT is chic and people have images in front of them of computer networks connecting the world. But at the end of the day, material products have to be made with a good old-fashioned machine at some point. And that is still about mechanics, cables, gears, motors, etc. They are the basis for making industry work. Today we are going to look at one of these devices: the multi-plate clutch. It is one of the elementary components that plays a major role in the drive technology of machines or vehicles.

What is a multi-plate clutch?

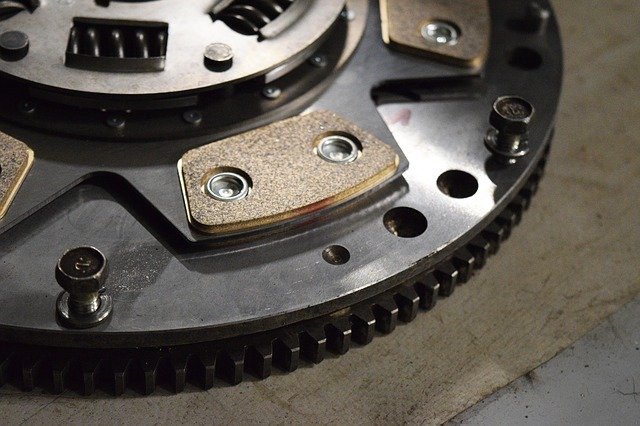

A clutch is a drive in which a drive train is connected to the gear wheel on the inside of a disc. This disc also has gears on the outside with which it transmits the rotation to other machine elements. The difference to a multi-plate clutch is that in the latter not only one disc is used, but several discs are installed in parallel next to each other. In this way, the entire force is not only passed on to one gear wheel, but distributed evenly over several. With the help of a suspension and a clutch rod, the discs can be shifted in such a way that idling occurs. See the video here:

What is the advantage of a multi-plate clutch?

Due to the use of fixed screw connections, it works backlash-free – according to the experts at Ortlinghaus multi-plate clutch. With such a design, even minimal play and movement are avoided and the strength is increased.

A multi-plate clutch can be switched under load.

Its design makes it possible to keep it small, i.e. to build it compact. At the same time, it is relatively inexpensive.

Where are multi-plate clutches used for?

The most important area of application in the automotive sector is in automatic transmissions and in the gearshifting of motorbikes. Their advantage there is that they can transmit a lot of power when starting up and allow only little wear even under high loads.

Furthermore, multi-plate clutches are also used as components in drive technology. There they are connected to construction machinery axles and are used as parking brakes. As a rule, they are located completely in an oil sump. Their advantage in this case is that they are stable and reliable. Machines with such a clutch are considered strong, powerful and, above all, durable. Their disadvantage is the lower coefficient of friction – compared to a dry clutch. In addition, they have a higher drag torque when idling. This idling torque means that more energy is needed to turn itself. This means that more energy is consumed when idling. On the one hand, this circumstance is due to the oil in which the blades are located. On the other hand, it is due to the type of pads used.